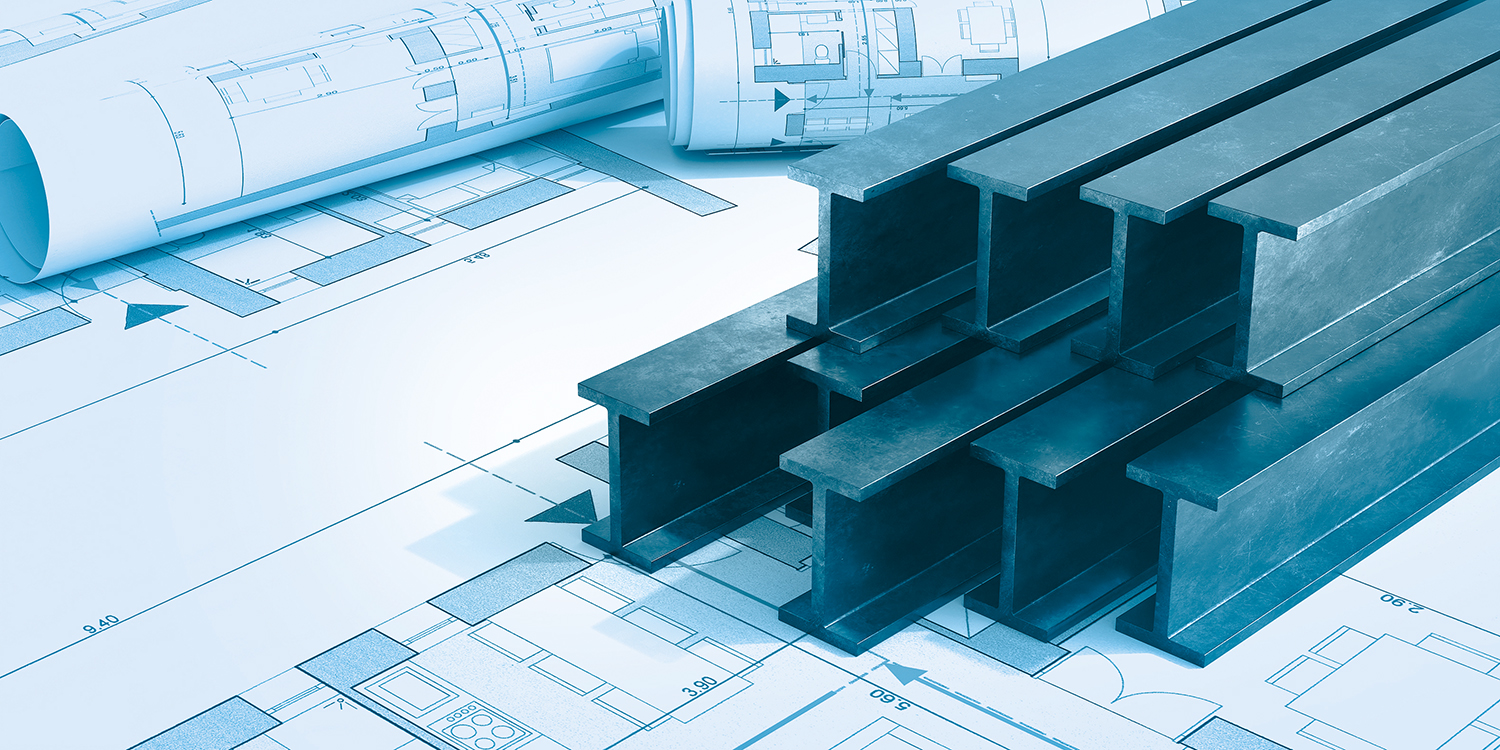

John Carpenter highlights the potential safety issues and the wider implications for designers and principal designers of not considering construction processes during design, including permanent works steelwork in temporary conditions

One would have thought that, after nearly 28 years of CDM, there would be nothing left to say on the subject of the designer’s role and duties. Embarrassingly, appallingly, this is not so. The general level of knowledge and action across the industry is still lacking – with exceptions of course – although these can be hard to find in the public domain.

A new guidance note, ostensibly about permanent works steelwork in temporary conditions arising during construction, gives emphasis to a risk management approach not widely adopted and yet which has significant potential. I wrote this note, Design Risk Management: Steelwork temporary conditions (reference 1) to capture known shortfalls in design and to give them greater prominence. It was published by the Institution of Civil Engineers (ICE).

It provides a reminder of the design risk management process, from both the permanent and temporary works designer’s perspective, for permanent works steelwork in the temporary condition arising during construction. There is an obligation on the permanent designer to consider these situations, highlight them if not obvious to a competent contractor and to make efforts to eliminate or reduce the consequential risks. Several commonplace examples are given. The principal designer should be asking if this has been done.

The steelwork advice note is one such example of what can be done to address design issues in the industry – two others are mentioned in the box on the right.

Poor design decisions

Even after all these years, designers are not good at thinking about construction processes (be it initial build or maintenance and repair). If we are to improve the standard of design, and buildability, with regard to the wellbeing of others, the best place to start is by thinking of those who may be harmed by poor design decisions.

These are contractors (both those who build and also those who maintain and repair) and those clients who have a long-term interest and who engage people to maintain and repair their asset.

Further resources

Design Risk Management: Steelwork temporary conditions, at Design Risk Management: Steelwork temporary conditions

Institution of Civil Engineers (ICE) ice.org.uk

Designing a Safer Built Environment, ICE Publishing

Essential consideration of soft hazards at Essential consideration of ‘soft hazards’ on civil and building engineering projects

CROSS, cross-safety.org

CROSS Alert at The Management of Design Related Risks: structural, civil and fire engineers

CROSS, cross-safety.org

Managing Health and Safety in Construction at Construction (Design and Management) Regulations 2015

hse.gov.uk

Paving slabs at Briefing Sheet: Health & Safety Expert Panel on Paving Slabs

Institution of Civil Engineers (ICE), ice.org.uk

Roof work: edge distances at Roof Work: Repair and maintenance

Institution of Civil Engineers (ICE), ice.org.uk

There are many clients, of course, who do not have a long-term interest or who do not have the necessary understanding of the operational phase of an asset. In these cases, the designer should consider the longer-term aspects and, if not confident in this regard, seek advice.

Furthermore, poor design is likely to lead to a higher cost to clients because contractors will add money into their bid in anticipation of difficulties arising from anticipated poor design. When bidding is tight, it will arise instead in claims during the project or shortcuts being taken. These cost-related scenarios are more likely than the contractor’s operatives suffering from harm, as the obligatory safe system of work will, in most cases, be a checkpoint.

This is not a good advertisement for designers or the industry. The key then is to identify commonplace poor design examples, or commonplace design information absence, and set out clear expectations such that it results in safe and healthy work tasks, is given authoritative status through industry organisations such as APS. Although not covered by legislation, we must also seek economic and sustainable solutions.

In addition to the traditional occupational safety and health issues (work at height, dust etc), the Building Safety Act has brought to the fore the need to consider structural failure and fire (although these were always there as statutory risks). If one studies these failures, occurring over the years, of whatever scale, and in any industry, one finds a common thread of root causes. These are mostly ‘soft hazards’, which include, as examples, checking, supervision/monitoring, validation and verification of software (See references 2,3,4).

Hiding in plain sight, these soft hazards are the ones which can cause not only serious safety situations, but also significant additional costs, delay and other detrimental effects. They are directly relevant to both designers and principal designers. Consideration of these hazards by designers and also principal designers should be a feature on all projects of any size and type.

Designers, encouraged by principal designers and others, should follow the advice given in the three referenced advice notes and, at an individual or project level, think through the construction phase in particular.

John Carpenter FICE is a past fellow of the Institution of Structural Engineers and of the Institution of Occupational Safety and Health. He is an ICE Gold Medallist 2021. He is past secretary of the Standing Committee on Structural Safety (SCOSS) and instigator of CROSS, founding secretary of the Temporary Works Forum (TWf) and past external memberof APS Council.

Further examples of ICE guidance on design

As well as the new safety note on steel design, the ICE has also produced two notes covering other aspects of design.

Safe PC slabs

The HSE CDM Guidance Managing Health and Safety in Construction at (para 87a) (reference 5) somewhat confusingly talks of designers “considering the use of smaller slabs” (so as to lessen health issues, it is supposed). However, no advice is given on how the choice might be made, or how this marries with the use of commonly available sizes. The ICE advice note (reference 6) provides the answer to this in a practical way.

Edge distances on flat roofs

Surprisingly, there is no specific formal guidance as to when edge protection measures should be implemented in situations when access is required, but only for competent persons, eg on plant maintenance. ICE produced this note (reference 7) to provide such advice. It makes clear that just because access on to flat roofs will occur, it does not mean that edge protection has to be provided in all cases.