Spot the robot dog, virtual reality and immersive rooms are all being deployed by AtkinsRéalis on the huge programme of work in the nuclear sector to make it safer and more cost efficient – but the application of innovative technologies doesn’t end there. Denise Chevin reports.

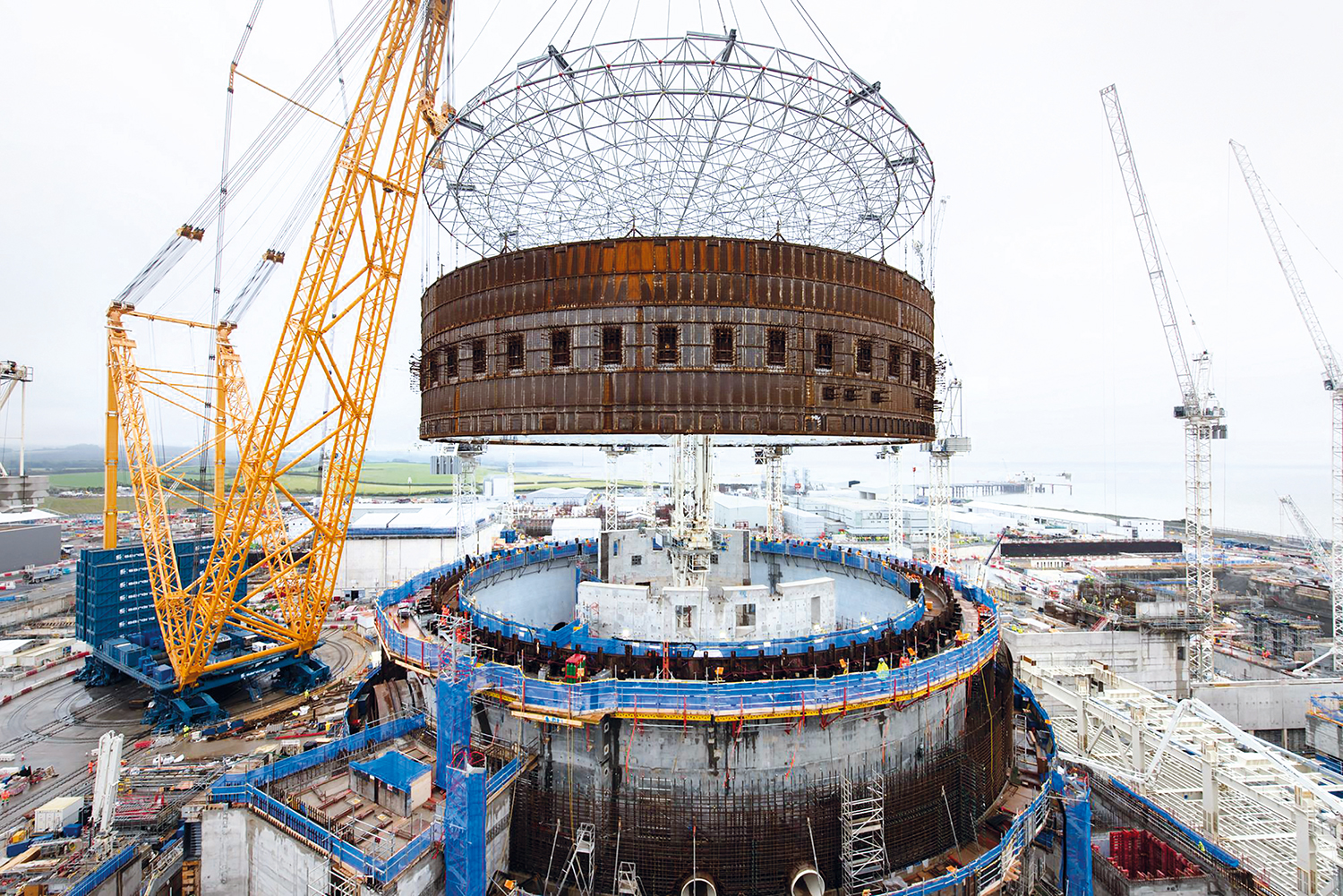

Nuclear power is in the ascendancy. Hinkley Point C in Somerset – currently the largest construction site in Europe – is the first in a new generation of nuclear power stations designed to support the UK’s ambition to reach net zero by 2050. EDF, the majority owner of Hinkley Point C, also hopes to build a second one – Sizewell C in Suffolk.

Meanwhile, in October, tech giants Google and Amazon both announced deals to use small nuclear reactors to generate the vast amounts of energy needed to power their artificial intelligence (AI) data centres in the US.

On top of the burgeoning new nuclear sector there is a burgeoning workload in decommissioning too, as older generators are retired from service.

With the sector’s renaissance comes a plethora of innovative processes and technologies. This includes AtkinsRéalis’s Virtual Site Access, a suite of technologies offered by the engineering giant that uses a variety of monitoring techniques to survey all types of nuclear facilities – whether operational, under construction or being decommissioned.

This allows remote planning, analysis and management of nuclear facilities across the life cycle. Allowing the work to be undertaken remotely reduces risks, makes it more efficient and saves carbon and money.

Between March 2023 and February 2024, the use of these remote services by AtkinsRéalis saved 20,118 hours of travel, an estimated £1.2m in costs (based on agreed client metrics), and 296,585kg of CO2, while also substantially reducing personnel radiation exposure.

Digital in Nuclear vision

The suite of equipment that makes up Virtual Site Access has been developed by AtkinsRéalis as part of its Digital in Nuclear vision – a strategy of harnessing digital technology to provide a comprehensive remote service to the sector, saving people having to travel to site and work in harsh conditions. Virtual Site Access won the Best Application of Technology Award at the Digital Construction Awards in July 2024.

The digital service includes many cutting-edge technologies, such as Boston Dynamics’ Spot the dog, and other quadrupedal robots, virtual reality (VR) harnessing Microsoft HoloLens 2 headset and Igloo Vision immersive spaces. Putting this package of technologies together has been masterminded by Darren Grears, director, head of digital, nuclear and power, EMEA, AtkinsRéalis.

Grears started as an apprentice in the company’s nuclear business, 23 years ago. “I have a decommissioning background working at Sellafield, and decommissioning is a good sandbox because of the challenges. Sites like Sellafield are so varied and broad that there’s really a strong sort of pull for innovation, technology and robotics,” he says.

Hinkley Point C is predicted to come on line before the end of the decade, while construction and commissioning of Sizewell C is expected in the mid-2030s – and Grears’ team is working on both.

Meanwhile, eight more nuclear reactors are due to go offline by the end of the decade, joining those already being overseen by the Nuclear Decommissioning Authority. The workload in the sector is enormous and demand for AtkinsRéalis’s services has grown rapidly.

“When we started the Virtual Site Access service in 2021 there were just four of us working full time on digital. Now there are close to 50,” he says.

So what is the thinking behind Virtual Site Access?

In the nuclear industry, sites are predominantly situated away from areas of high population and therefore lack effective transport links. When combined with the necessary security restrictions (training, clearance etc), it makes accessing these sites difficult, explains Grears.

Added to site access issues are the inherent risks of the nature of the sites, both conventional and radiological. Furthermore, data security and information assurance also restrict people from being able to visualise the site. “Being able to virtually access the site remotely through the web removes all these limitations and restrictions,” he says.

AtkinsRéalis is providing services to assist and prolong the running of nuclear plants that have their lifespan extended to maintain energy security while new generation capacity is being built.

“One of the ways we’re using Virtual Site Access is in deploying technology to collect site information about a plant, enabling the generation of 3D models of the current plant configuration. Drawings generated when plants were built rarely reflect the current configuration. For example, it might be there has subsequently been a change of configuration where a walkway is no longer accessible,” says Grears.

One of the most advanced technologies being deployed is Boston Dynamics’ quadrupedal robot, Spot, which acts as a vehicle to mount a load of sensors to collect information more autonomously to assist decommissioning activity. Spot was deployed to reduce risk in decommissioning at Calder Hall in Sellafield, which was the world’s first full-scale commercial nuclear power station.

“When it was built in the 1950s materials included what we now know to be dangerous, primarily asbestos, so it is far less risky to survey the building remotely. The team used Spot to carry out a building inspection remotely while streaming the visuals live to a project team in an offsite location. The team were able to communicate with Spot operators in real-time for a bespoke inspection.

Grears explains: “The building was classified as ‘no person entry’, so the team de-risked that whole operation by remotely controlling Spot to complete the walk around the building, doing a virtual tour of the facility.

“This inspection allowed the project to progress on what could have previously been a stalled task.”

Immersive rooms

In what it describes as a ‘leading edge’ investment AtkinsRéalis has built three immersive rooms in the UK, with another three coming online globally by the end of this year.

“Immersive rooms are 360° projection rooms (like sort of BIM Caves in traditional speak). We’re installing them in key locations across our UK offices. They are linked to our Virtual Site Access initiative to allow users to have group interaction with data as well as viewing it through VR,” says Grears.

“Rather than physically having to go to site, we have the ability to bring people to the site by entering the immersive room; you can load project data and then have a 360° view of the information that’s being collected.”

These immersive rooms can be used to virtually access sites for training, for inductions and to avoid having to be physically present to plan an activity. And when staff do have to go physically to site, the immersive room can be used to understand in advance what the site will be like.

Are there other applications outside nuclear? “Yes, we are using it to survey other power and network infrastructure, like plants and substations, but it can be used on any asset that requires inspection or further analysis,” says Grears. “One area we could see greater demand is in rail – to reduce risks and find safer ways to conduct surveys and tasks.”

How might the technology continue to develop?

The team still needs to be on site to deploy the technology that forms part of Virtual Site Access, though it can still operate beyond visual line of sight.

“We’re working now towards that being fully autonomous and controlled from miles away. So, we would station Spot in a ‘kennel’ on a site permanently and then deploy it to carry out autonomous data collections regularly.

“We also want to explore how we can use machine learning to analyse the data we have collected to identify risks. We can use generative AI to start asking questions of it.

Should people be worried robots might start taking their jobs?

“It’s not about replacing people – it’s more about succeeding in a very competitive market and overcoming future skills gaps: that’s where the robotics comes in,” explains Grears.

“We also need to be attracting people like gamers who do not necessarily associate construction with the cutting edge of digital technologies. We need data scientists and we need software engineers. And we also need to train and pass on knowledge to a younger generation of workers, as many who have worked in nuclear for their entire careers are now retiring and that experience and understanding of site and conditions could be lost,” he adds.

The company has started to recruit people from different areas to widen the skills base. “We’re trying different tactics, like holding a hackathon to reach people who wouldn’t have otherwise considered this as a careers field and help get our name out there as a company scaling up its technology teams. We hope it will bring in creative people with ideas that we will look to support and invest in,” Grears explains.